Function description:

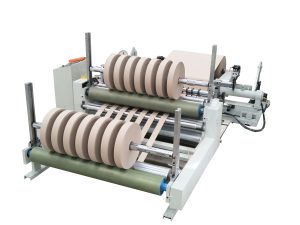

FA-1600-200-2 is the standard version of the two-axis slitter

Double-axis winding, separate roll space, flat end face

The winding center of gravity is higher than that of single-axis winding, and the winding speed is slower than that of single-axis winding.

Discharge method is manual discharge

Remarks: There are two methods of brake control: magnetic powder tension automatic control and manual hydraulic brake. Customers can choose according to actual needs when ordering.

Features:

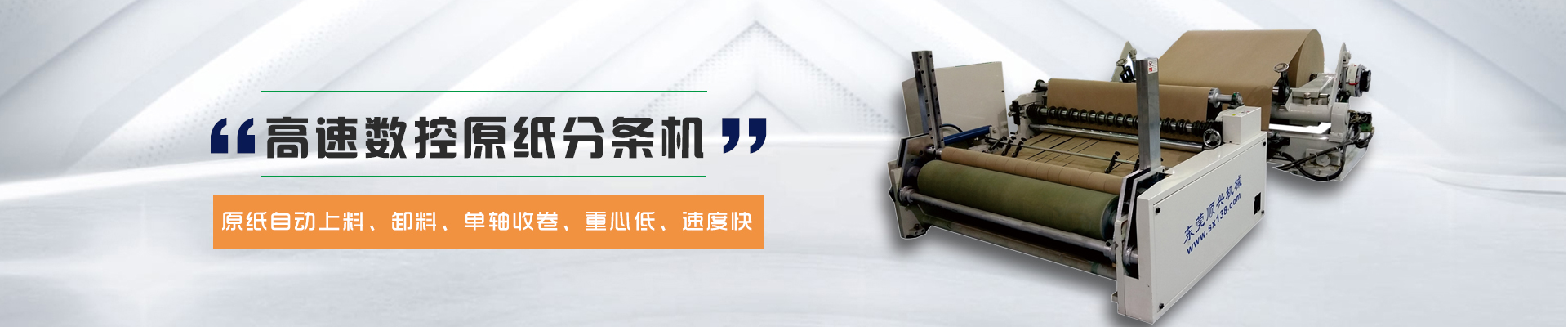

High-speed CNC base paper slitting machine is used to cut and wind wide webs into various narrow webs suitable for production needs according to different needs during the production process. The slitting process includes two processes: slitting of the raw paper roll and winding of the finished paper roll. This machine is based on the original electronic control system, adding automatic edge alignment, automatic knife positioning and other functions, so that the mechanical performance has reached the desired effect, making the machine more stable at high speeds, smooth winding, simple and convenient operation Safe, reliable and durable. This machine adopts the design of fast roll-up and roll-unload, which is in one step. Loading and unloading can be done automatically by pressing the switch. Stepless speed regulation system is adopted, and the speed of the machine is adjusted by manual stepless speed regulation during use. The operating man-machine interface uses Mitsubishi touch color screen, which can directly input a variety of stripe widths, and is equipped with manual and automatic conversion functions.

The main technical parameters:

| Base paper width range | 800-1600mm |

| Maximum base paper diameter | 1300mm |

| Base paper weight range | 60-500G |

| Minimum stripe width | 40MM |

| Rewinding diameter | 700MM |

| Slitting speed / minute | 200 m / min |

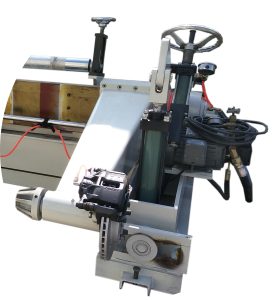

| Feeding method | Hydraulic (shaftless) |

| Feeding method | Manual |

| Winding method | Single axis φ76 |

| Braking method | Hydraulic-Manual / Magnetic Powder-Full Automatic |

| Knife positioning | Semi-automatic / manual |

| Clamping taper | Standard 3 inch (6/8/12 optional) |

| Cutter | 20 set |

| Meter counting | Automatic |

| Speed control | Frequency |

| Input voltage | 380 (3P) |

Electrical control configuration

| monitor rate | 5.5KW |

| Inverter | Mitsubishi |

| PLC controller | Mitsubishi |

| Touch screen | Mitsubishi |

| Spindle bearing |