At present, the beverage industry's degree of attention to aseptic cold filling production lines has reached a new level, and the use of aseptic cold filling equipment by beverage production enterprises has become an inevitable trend.

The investment cost of aseptic cold filling production line has always been the concern of the beverage industry. With the continuous reduction of equipment costs by equipment suppliers, the investment cost of paper tube machines for aseptic cold filling production lines has been reduced to 1.5 of the hot filling line. ~ 1.6 times, and the supplier of domestic aseptic cold filling production line of paper tube machine has also matured continuously.

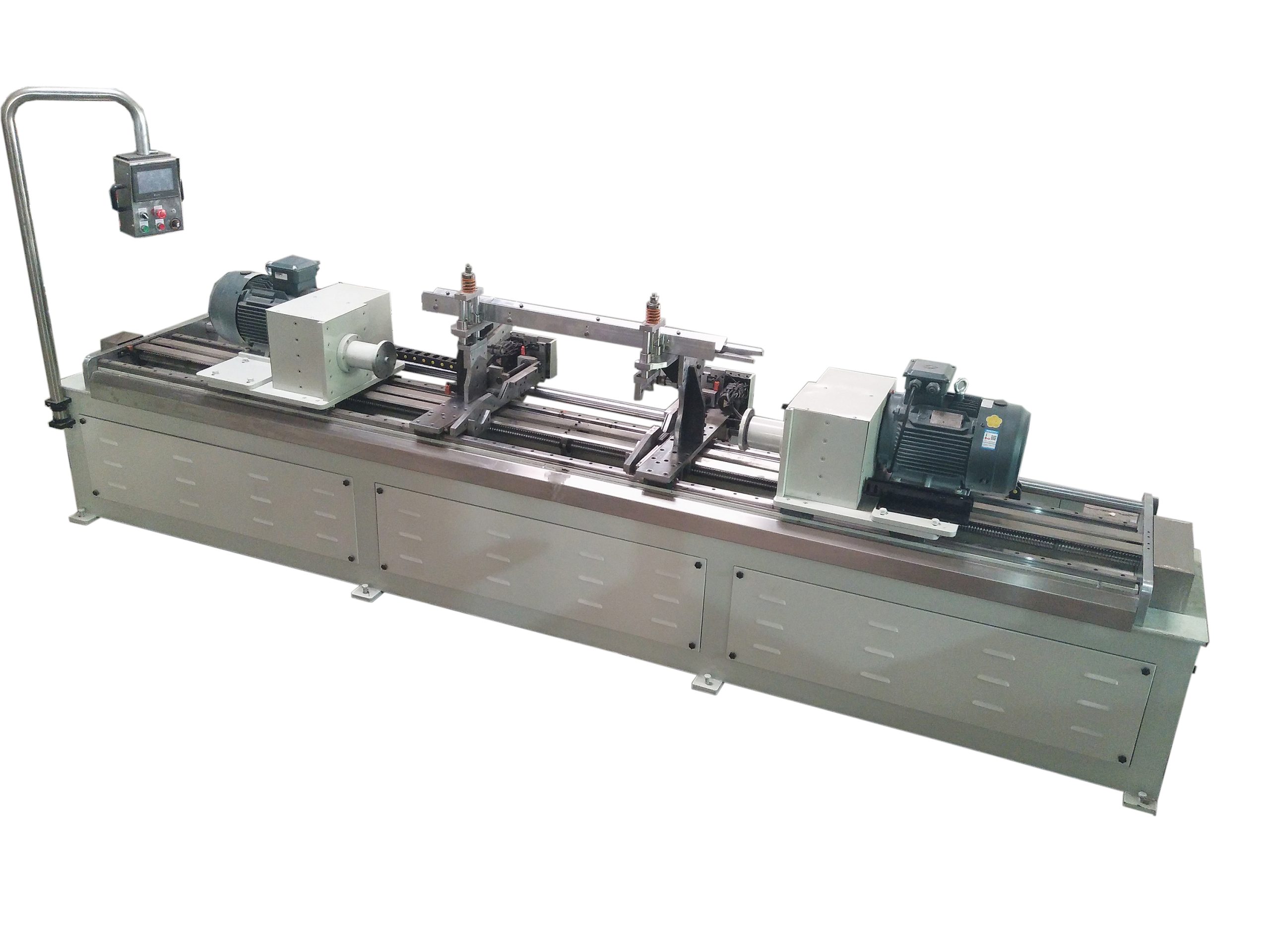

Filling equipment Paper tube machine is the most core equipment on the production line. Whether the filling equipment can be quickly converted has attracted widespread attention from enterprises. Because when producing different products or different bottle types, the filling equipment will lose valuable filling time and reduce production efficiency due to the conversion of paper tube equipment.

New development of paper tube machine

There are so many things in the world, and the existence of everything is not invariable. The paper tube machine industry in China is no exception, either progress or backward. So how to improve the development of this industry? This has become a common concern of paper tube machine manufacturers.

Nowadays, the paper tube machine, web paper slitting machine, tube cutting machine, paper tube machine are upgraded and replaced by Japan, which is leading the way, making a lot of dollars in this field. The four little dragons in Southeast Asia also followed Japan's lead, and have performed well in the manufacturing of packaging machinery and equipment and production lines. In the European Community, the pace of upgrading packaging machinery and equipment and production lines in Italy is much faster than that of other member states.

So where did they improve? Update is key!

The replacement method is to replace local parts, components or critical components and key technologies, so as to achieve the purpose of replacing a unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, models and assembly methods, etc. Get updated. In this way, most parts and unit parts are reused, which not only improves the value of equipment, but also saves raw materials and a large amount of labor, and reduces costs.

This development trend shows that paper tube packaging equipment, paper tube machines, web paper slitters, tube cutting machines, paper tube machine equipment, spiral paper tube machines are becoming more and more standardized, serialized, integrated, assembled, Development of online models. Civil and military high-tech will also enter the entire packaging machinery and equipment field more and more widely. The fierce market competition will undoubtedly accelerate the upgrading and technological transformation of paper tube packaging equipment in various industries.

Operation principle of paper tube machine under different control systems

1. From the working mode of the paper tube machine, in the relay control circuit, when the power is turned on, all the relays in the circuit are in a restricted state, that is, the pull-in relays are closed at the same time. The relay is limited by certain conditions and cannot be pulled in. This kind of working mode is called parallel working mode. The PLC's user program is executed in a cyclic order. Therefore, each soft relay is in a cyclic scan. The sequence of each relay subject to the same condition is determined by the program scan sequence. This working method is called serial. Way of working. 2. From the control method of the paper tube machine, the control logic of the electrical control system uses hardware wiring, and the control logic of the relay mechanical contacts is connected in series or parallel. The PLC uses computer technology, and its control logic is stored in the memory as a program. To change the control logic, you only need to change the program, so it is easy to change or add system functions.